Fuels Technology

Advancing Multi-Functional Fuel systems with Lignin-Hemicellulose-Depolymerized-Organics (LHDO™), including non-food based HEFA feedstocks for SAF, Gasoline and Diesel and high-performance additives to assist in reducing emissions

SixRing™ sustainable, plant-based LHDO™ biocrude is fractionated to a heavy, intermediate, and light fraction at our facility level and can be utilized as a multi-functional diesel additive, high volume diesel replacement and HEFA feedstock.

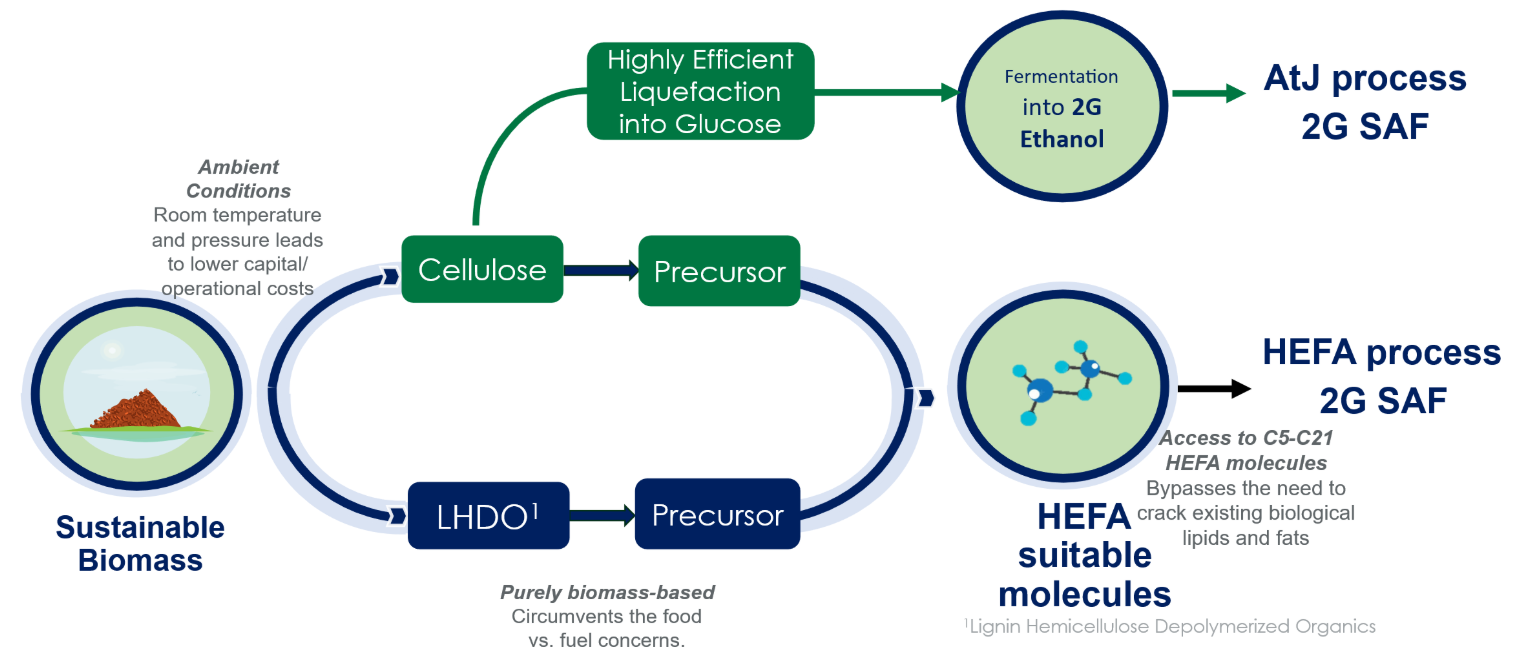

LHDO™ and Cellulose Platforms:

High Performance, multi-functional diesel additives

LHDO™ & Cellulose based HEFA feedstock

High value fine chemicals and materials

Multi-application corrosion Inhibitors

Bio-resins / Binders

Stimulose™ additive for RNG production increase

Concrete Self-Healing MCC and NCC additives

Fuel Additives and De-Carbonization Solutions

6RLu-400

Plant-Based Innovation for Cleaner, More Efficient Diesel Performance

SixRing™ fuel additive solutions are engineered to address the critical challenges of modern diesel engines operating on ultra-low sulfur diesel (ULSD). As traditional lubricity agents are removed during refining, engine systems are left vulnerable to wear, corrosion, and inconsistent combustion—especially in demanding rail, marine, and heavy-duty fleet applications.

Our flagship product, SixRing™ 6RLu-400, is a high-performance, lignocellulosic (non-food, plant-based) additive designed to restore and enhance fuel functionality while lowering environmental impact.

Proven Benefits:

Enhanced Lubricity

Reduces wear scar by over 300%*, protecting pumps, injectors, and fuel system components. *Based on loadings.Corrosion and Conductivity Protection

Prevents oxidation and microbially induced corrosion, improving long-term fuel system integrity.Emission Reductions

Demonstrated reductions in CO₂ (up to 4%), NOx (~1%), and particulates (up to 20%) through cleaner combustion at only 1% loading.Production & Import Security

Potential to reduce imports & production of fossil-based diesel fuel up to 50%.Improved Fuel Economy

Oxygenated formulation supports more efficient fuel burn and lower total cost of operation.Cold Weather Performance

Ester-based chemistry remains effective in extreme low temperatures with pour point below -42°C.

SixRing™ greatly advances these proven pathways. Our technology enables both first-generation (1G) ethanol facilities to produce advanced 2G ethanol from non-food biomass with no capital expenditures. By using our ultra-high yield cellulose systems industry can significantly reduces both capital investment and operational costs, creating a faster, more economical path to scale using existing infrastructure.

SixRing™ Non-Food Pathway to Alcohol-to-Jet (AtJ)

This “1G–2G Ethanol” Approach Means:

Seamless Integration

Adaptable to existing ethanol plants, eliminating capital investment and expediting deployment.Certified Pathway

Builds on a globally recognized AtJ SAF process already approved for commercial aviation.Feedstock Flexibility – Expands supply by processing diverse waste and non-food biomass sources.

Lower Cost Structure – “Drop-In” ethanol production feedstock eliminates 1G to 2G facility conversions or greenfield facility capital expenditures.

Deep Carbon Cuts – Delivers significant lifecycle GHG reductions compared to fossil-based jet fuel.

SixRing™ Non-Food Feedstock Pathway to HEFA Infrastructure Produced Gasoline,

Diesel, and Aviation (SAF) Fuels

The SixRing™ HEFA Approach Means:

Seamless Integration

Adaptable to existing HEFA facilities, eliminating capital investment and expediting deployment.Feedstock Flexibility – Exponentially expands global supply by processing diverse low-value non-food biomass sources.

Lower Cost Structure – “Drop-In” feedstock eliminates facility conversions or greenfield facility capital expenditures.

Increased Asset Diversity – Allows existing facilities to produce sustainable Gasoline, Diesel and Aviation Fuels based on market metrics.

Certified Pathway - Builds on a globally recognized AtJ SAF process already approved for commercial aviation.

The Hydroprocessed Esters and Fatty Acids (HEFA) pathway is one of the most established and widely approved routes for producing Sustainable Aviation Fuel (SAF) under ASTM D7566. By refining renewable lipids—such as used cooking oil, tallow, or algal oils—into high-quality paraffinic kerosene, HEFA delivers a drop-in jet fuel that works seamlessly with today’s aviation infrastructure.

SixRing Pathway to SAF via HEFA and AtJ

SixRing Pathway to Fuels via HEFA

SixRing’s globally patented processes and products means existing HEFA assets could viably produce 2G fuels without significant refit. Proven and mature HEFA assets can now be considered for expansion despite increasing feedstock supply risks and changing government policies. With the advent of SixRing™ derived 2G feedstocks and future global supply via dozens of facilities progressing to FID there is now a viable pathway to support heavy industries transition to lower emission Gasoline, Diesel, and Aviation fuels.

Renewable Natural Gas (RNG)

Enviro-Cel Stimulose™

A cellulosic product made from non-food based sustainable lignocellulosic biomass using a proprietary process. This product is a high-performance, plant-based additive for anaerobic digestion designed to enhance methane generation and decrease hydrogen sulfide (H2S) production.

Increase in methane generation observed after the addition of Enviro-Cel Stimulose™ in a digester at a 2.3 % dry wt./wet wt. loading, Fig. Corresponding methane yield increase.

Improved Economics By Using SixRing’s Cellulose

Significantly lower input costs when the cellulose is used as a supplement

Reduced feedstock volumes / costs

Download the Brochure or Product Data Sheet below to learn more about how Stimulose™ can unlock greater value from your biogas operations.

Lower processing costs

The core advantages of the SixRing technology platform over other biomass-to-energy/materials processes are:

-

Underutilized Feedstock

No practical limit to the feedstocks, including blends of feedstocks

-

Non-Food

All feedstocks are non-food based and typically low-value

-

High Yields

Nearly 100% of biomass is converted into saleable products

-

Ambient Pressures & Temperatures

Significantly lower energy requirements (core process generates heat for capture and use)

-

Process Chemical Recovery

High recovery and recyclability of process chemicals

-

Gentle Core Process & Fine Molecules

Products and fine molecules are largely unaltered from natural state and remain in products, resulting in high value

-

Three Main Product Streams

(Cellulose, LHDO and biochemicals) – all three address existing market challenges and sustainability demands

-

Continued Optimization and Processing

Results in additional revenue streams

-

Product Refining and Upgrading

Existing infrastructure can be used to refine, process, and distribute products produced by the SixRing process

-

Low Capital and Operating Cost

Simple design and commodity inputs

-

Use of Existing Infrastructure

Certain industrial facilities can be converted to the SixRing technology processes using existing infrastructure, such as renewable diesel and kraft facilities

-

Low Carbon Intensity

Ranging from 50% to 80% lower than fossil based equivalent fuels

The SixRing™ process is compatible with all types of lignocellulosic biomass with numerous strategic

partner-supplied feedstocks from five continents already successfully deconstructed and cataloged via the company’s delignification process. These efforts have proven there is no reliance on any sole feedstock, greatly increasing its global viability. We have already categorized over 80 high value fine chemicals, materials, additives, and fuels proving the diverse applications of our products into almost every industry.

Contact us for more information.